Oral dental CAD/CAM digital manufacturing follows a streamlined workflow that significantly reduces patient waiting time compared to traditional methods. Using CAD/CAM technology and equipment, the process typically includes the following steps:

The dentist conducts a thorough oral examination, takes X-rays, and discusses the treatment plan with the patient. This ensures that both the dentist and patient have a clear understanding of the proposed restoration.

The dentist removes decayed tissue and shapes the teeth to create an optimal surface for restorations, such as crowns, bridges, or inlays. The color of the restoration is then matched to the patient’s natural teeth to determine the appropriate shade.

A handheld intraoral scanner is used to capture a precise 3D image of the teeth and surrounding oral structures. This digital impression provides accurate data for the restoration design.

The 3D scan data is imported into CAD software, where the dental technician designs the restoration. The design ensures proper shape, fit, occlusion, and aesthetics.

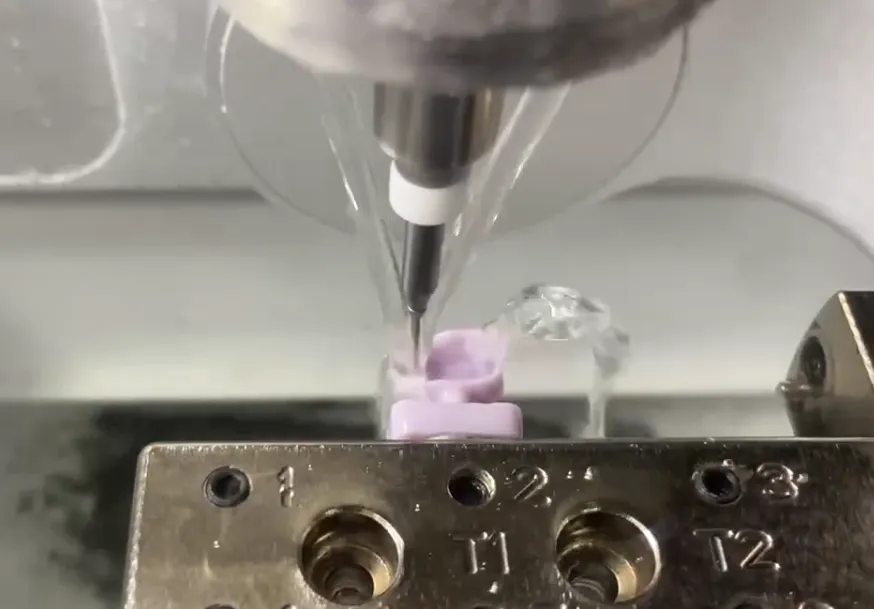

The restoration is milled from the chosen material—metal, resin, zirconia, or all-ceramic—using a dry or wet milling machine. Precision milling ensures the restoration matches the digital design, which directly affects comfort, function, and appearance.

The restoration is tried in the patient’s mouth to check the fit, bite, and comfort. Any necessary adjustments are made before final processing.

High-temperature sintering crystallizes the material, increasing its strength and giving the restoration a natural tooth-like color.

The restoration is polished and glazed, then baked in a porcelain oven to fix the enamel layer and enhance durability. This step ensures the restoration closely resembles natural teeth in appearance and translucency.

The dentist cleans and disinfects the restoration before permanently cementing it in the patient’s mouth. Proper placement ensures stability, function, and long-term comfort.

CAD/CAM digital dental technology enhances patient comfort and satisfaction while improving the efficiency of dental clinics and laboratories. This workflow delivers faster, more precise, and aesthetically pleasing restorations, benefiting both patients and dental professionals.