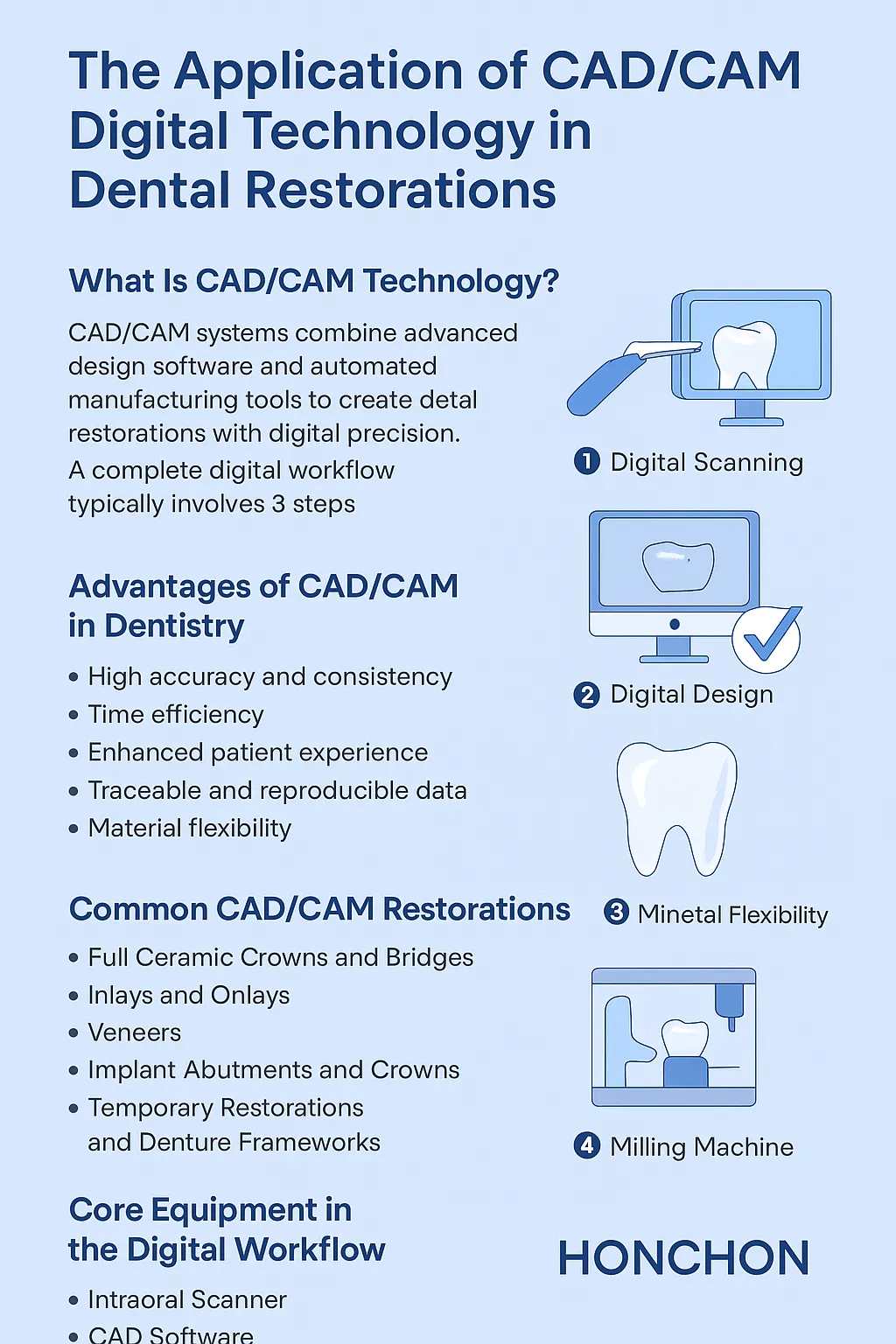

Digitalization has become an unstoppable trend in modern dentistry. Among the most influential innovations is CAD/CAM technology—short for Computer-Aided Design and Computer-Aided Manufacturing.

This technology has transformed the way dental restorations are designed and produced, enabling faster, more precise, and more consistent results for clinics and dental labs worldwide.

CAD/CAM systems bring together advanced design software and automated manufacturing tools to create dental restorations with digital precision.

A complete digital workflow typically involves three main steps:

Digital Scanning – Intraoral scanners capture the 3D shape of a patient’s teeth and gums, replacing traditional silicone impressions.

Digital Design – Using CAD software, dentists or technicians design restorations such as crowns, bridges, inlays, or veneers directly on screen.

Digital Manufacturing – The design file is sent to a milling unit or 3D printer, where restorations are precisely milled or printed from zirconia, glass ceramics, PMMA, or other dental materials.

This seamless process connects every stage—from data acquisition to final restoration—creating a faster and more predictable workflow.

Compared with traditional manual methods, CAD/CAM technology offers clear benefits in terms of efficiency, precision, and patient comfort:

High Accuracy & Consistency – Digital scanning minimizes human error and ensures a precise fit between the restoration and natural dentition.

Time Efficiency – Digital design and milling can significantly shorten fabrication time; some restorations can even be completed in a single day.

Enhanced Patient Experience – No messy impression trays or discomfort during data collection.

Traceable & Reproducible Data – Digital files can be easily stored, modified, and reused for future treatments.

Material Flexibility – Supports a variety of high-performance materials including zirconia, lithium disilicate, and PMMA for both strength and aesthetics.

CAD/CAM systems are versatile and can produce nearly all types of fixed dental restorations, such as:

Full Ceramic Crowns and Bridges

Inlays and Onlays

Veneers

Implant Abutments and Crowns

Temporary Restorations and Denture Frameworks

Through digital design, dental professionals can precisely control shape, occlusion, and margin fit, achieving restorations that are both functional and esthetically pleasing.

A complete CAD/CAM solution typically includes:

Intraoral Scanner – Captures accurate 3D digital impressions.

CAD Software – Designs restorations and analyzes occlusion.

Milling Machine – Transforms the design file into a physical restoration.

Sintering Furnace and Finishing Tools – Used for high-temperature sintering, glazing, and polishing.

As a professional dental equipment manufacturer, HONCHON provides a full range of digital solutions — including zirconia blocks, glass-ceramic blocks, PMMA discs, milling burs, sintering furnaces, and dental scanners — to help clinics and labs establish efficient, reliable CAD/CAM production systems.

The development of CAD/CAM dentistry is closely linked with advancements in AI, materials science, and 3D printing.

Artificial intelligence will soon play a role in automating design processes and optimizing occlusion.

Meanwhile, new hybrid ceramics and biocompatible composites continue to improve the balance between strength, translucency, and esthetics.

As digital manufacturing becomes faster and more cost-effective, chairside restoration will become increasingly common, bringing same-day treatment within reach for more patients.

CAD/CAM technology marks a new era in dental restoration — from traditional craftsmanship to intelligent digital production.

For dental professionals, it means improved precision and efficiency.

For patients, it offers a more comfortable and esthetic treatment experience.

And for manufacturers like HONCHON, it represents continuous innovation and responsibility in supporting the digital transformation of global dentistry.

HONCHON remains dedicated to providing high-quality dental materials and equipment, empowering clinics and laboratories to achieve better, faster, and more reliable results in every restoration.